The most important, and often overlooked, part of a fixed RFID asset tracking project is the RFID asset tag. This component of an asset tracking project allows you to receive and capture data instantly and effectively with RFID technology without requiring line of sight.

In this article we are going to discuss:

- Importance of the RFID asset tag

- Main Components of an RFID tag

- Questions to help you choose the best RFID asset tag

For a refresher, be sure to look at the 3 Components of a Mobile RFID Asset Tracking Solution for a brief overview before we take a deep dive into RFID Asset Tags.

Importance of RFID Asset Tags

There are a few important factors that you will look at when choosing the proper RFID tag for your project.

- Durability

- Read Range

RFID Asset Tag Durability

When choosing an asset tag, you want a tag that will survive for the life of an asset. Tagging assets is the most time consuming and expensive part of an asset tracking solution because of the labor commitment it takes to apply the tags to the assets.

Because you are investing all of the time and labor to apply tags, your #1 objective is for the tags to survive, not fall off, and be able to read through all conditions. Reapplying tags is frustrating and expensive.

When choosing your tag you need to factor in:

- What will the tags be exposed to?

- Abrasion?

- Chemicals?

- Weather elements?

- Heat or Cold?

- What materials and adhesive is used in the construction?

RFID Tag Read Range

The read range of a UHF RFID tag gives you the distance you can achieve between an RFID reader and tag to capture the data. Passive UHF RFID tags do not have a battery, instead, they are powered by the reader. When the reader is within range of the tag, it will power the tag to transmit the data back to the reader.

A few factors will determine read range:

- The surface the tag is applied to

- A metal surface requires a special on metal RFID tag. The best RFID tag for on metal surfaces can be found at Metalcraft.

- The size of the RFID antenna

- A common rule of thumb for read range is the larger the RFID antenna, the longer your read range will be.

- To determine the size of the RFID tag, you first have to consider the size restrictions you have for the asset you will be tagging.

Main Components of RFID Asset Tag

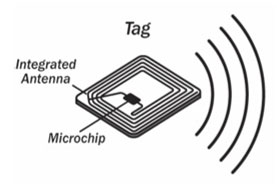

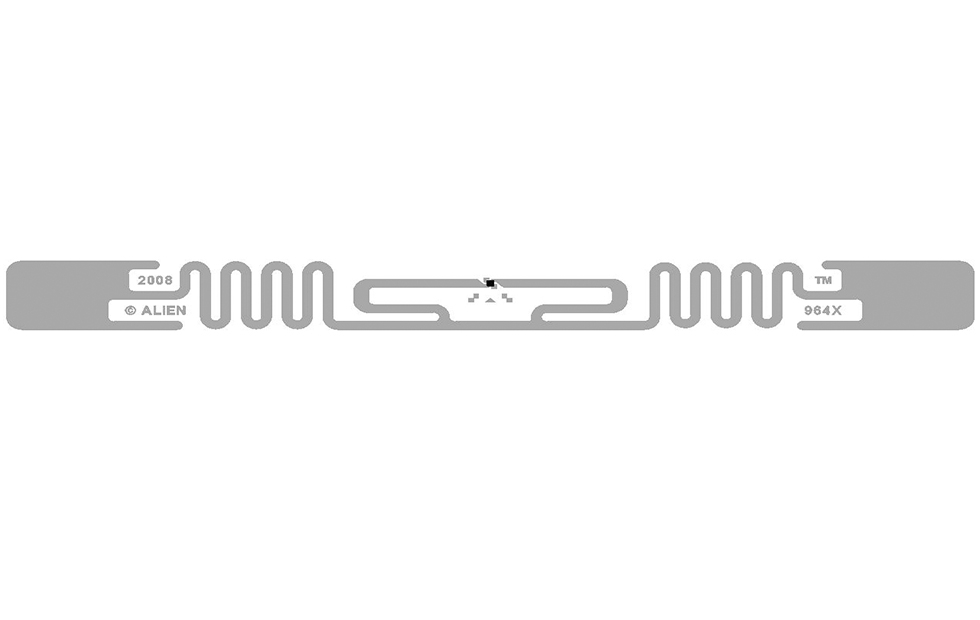

The construction of the RFID asset tag can be broken down into 4 main parts.

- Integrated Circuit (IC)

- Antenna

- Substrate

- Adhesive

Integrated Circuit (IC)

The Integrated Circuit, also know as the IC or microchip, makes the decisions and provides memory to store data. Using a passive UHF RFID system, the power to operate the IC is generated from the radio waves transmitted by the reader antenna. The microchip will attach to the antenna.

Antenna

The antenna collects the power from the radio waves transmitted by the reader and powers the IC. The larger the antenna the easier it is for the tag to collect the power, hence, a larger read range. Once the antenna receives the signal from the reader, it will transmit the received signal back. Think of the antenna as the “ears” of the RFID tag.

Substrate

The substrate of an RFID tag will encapsulate the integrated circuit and antenna which protects these two components. Polyester is a common substrate used for the best RFID asset tags because it gives extra protection from abrasion, chemicals, and other outside elements.

Attachment Adhesive

To properly apply an asset tag to a fixed asset, it is critical that the RFID tag you choose has an aggressive, permanent adhesive that will adhere to the surface of your asset. Because all surfaces are different, there are adhesives designed to work best on specific surfaces whether it is metal, glass, or plastic, or smooth or rough surfaces. Consulting with an RFID tag and label expert will help you determine best adhesive so you can rely on the tag staying on the fixed asset forever, no matter what kind of environment the tag is exposed to.

Questions to Determine Best RFID Asset Tags

Some questions you can ask yourself when choosing your RFID asset tag for your fixed asset tracking project:

- Is there a size restriction when tagging you assets?

- What is the surface you are going to be applying the RFID asset tag to?

- Is the surface curved or flat?

- TIP: Flat surfaces are recommended to achieve best read range results

- How far of a read range is desired?

- Will the tag be exposed to any chemicals, abrasion, hot or cold temperatures, or outside weather elements?

- Will there be any custom printing or programming?

With the answers to the questions above, it will help determine the best substrate, antenna, and chip combination for best results.

Conclusion

Choosing the proper RFID asset tag is vital to your overall asset tracking project’s success. Understanding the components and how to choose the best RFID asset tag and RFID readers for your project will give your company the best chance of success utilizing RFID technology.

To get a better understanding of the entire RFID asset tracking system, including RFID asset tags, be sure to check out The Anatomy of a RFID Mobile Asset Tracking System.

If you want to see Grey Trunk RFID software and RFID asset tags in action, feel free to schedule a 30 Minute live demo here.