Many companies — large and small — are starting to see the benefits of implementing a fixed asset tracking solution. Accuracy of their data and financial records on assets are more important than ever to reduce costs, being prepared for audits, and saving time.

A fixed asset can be defined as: “assets which are purchased for long-term use and are not likely to be converted quickly into cash, such as land, buildings, and equipment”

Examples of Fixed Assets:

- IT Assets

- Manufacturing equipment

- Tools for construction companies

- Biomedical equipment

- Returnable shipping containers

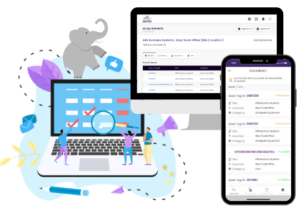

A fixed asset tracking system can help companies know three main things about their assets:

- What assets they have?

- Where they are?

- How the assets are?

Having an asset tracking system in place can help you answer these questions in a matter of seconds since you will have all that information at your fingertips.

There are three main types of asset tracking systems:

It can be confusing deciding between which option will work best for your company, so let’s take a closer look at the advantages and disadvantages of all three.

Excel File for Fixed Asset Tracking

Keeping track of your company’s assets on an Excel file is one way to ensure you have record of purchased assets. This is an extremely labor intensive process that requires manual entry of data.

Advantages:

- Economic alternative to barcode or RFID

- Easy to learn

- Available on any computer

Disadvantages:

- Human error / inaccuracy

- No real time data

- Access for only one person

- Time consuming / labor intensive

Excel files can work for some organizations, but many will start seeing limitations and inefficiencies with this compared to a barcode or RFID system.

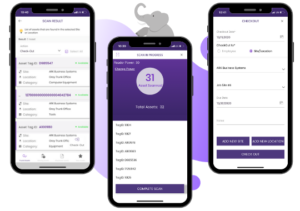

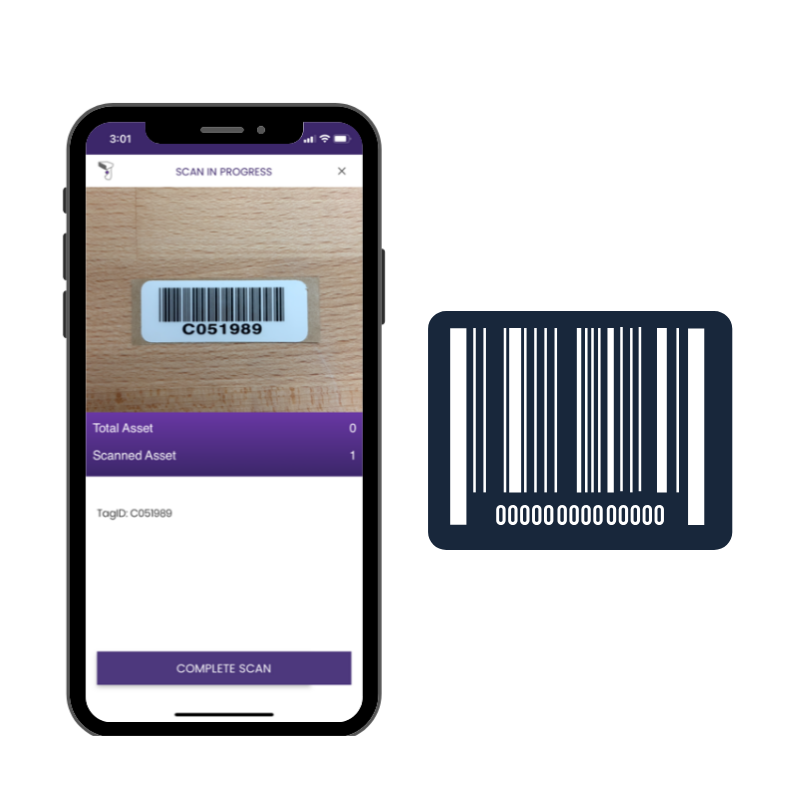

Barcode for Fixed Asset Tracking

Barcodes have been around since 1974 when the Wrigley gum company put a barcode on their gum package and changed the supermarket industry forever — see the history of the barcode here.

Since then, there have been many use cases for the barcode, including fixed asset tracking. Simply applying a barcode label to your asset allows for unique serial identification, much like a license plate. Once scanned, you can access all the information stored on that specific piece of equipment from the serial number.

Advantages:

- No data entry errors

- Improved efficiency for entering data

- Barcode tags are inexpensive

- Minimal hardware costs

HINT: There are no hardware costs if you use a mobile asset tracking system — your mobile device’s camera can scan barcodes.

Disadvantages:

- Line of sight required for each asset

- Very close read range

- Barcodes could become damaged

Barcodes systems are commonly used for fixed asset tracking because they have many advantages. However, as with any technology, there is always room for improvement. This leads us to our last type of asset tracking system, RFID.

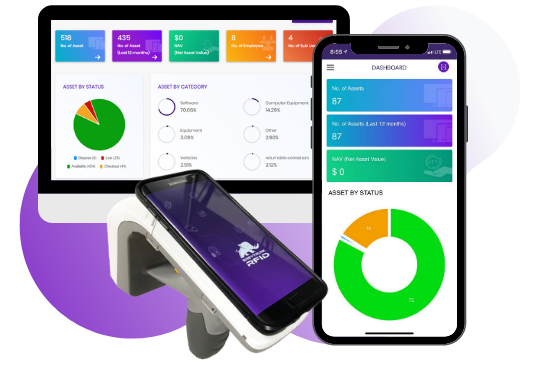

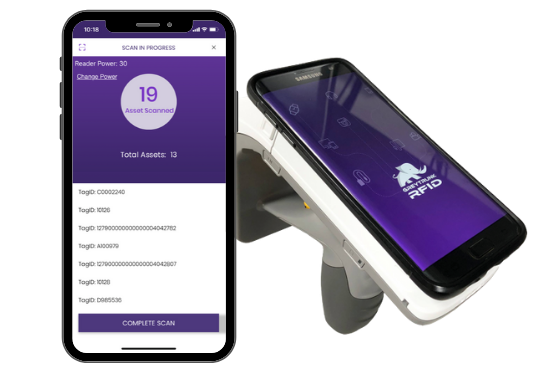

RFID for Fixed Asset Tracking

RFID, or Radio Frequency Identification, is the latest technology to enter the asset tracking world — specifically UHF RFID. Simply put, RFID is a barcode on steroids.

There are many features that an RFID system has compared to a barcode system, but as with any technology, there could be some limitations based on your company’s requirements.

Advantages:

- No line of sight is required for the tag

- Long read ranges

- Readers can scan multiple tags at once

- No human error

- Reduce inventory time

- Tags can use both RFID and Barcode, such as these from Metalcraft.

Check out these 5 Benefits of RFID Asset Tracking

Disadvantages:

- RFID requires more investment than barcode

- Surface dependent — — liquids and metals can affect the read range of tags

RFID has greatly improved over the years and is now becoming more accessible to companies of all sizes — large or small — to implement and see an ROI. Tags are becoming less expensive and the technology is making its way to mobile devices which makes implementation easier, faster, and more efficient.

If you are interested, check out a more in-depth breakdown of the Barcode vs RFID debate.

When you are deciding on a fixed asset tracking system — whether it is an excel file, barcode, or RFID system — it is extremely important that any system is only as good as the people and processes you have in place at your company